Diastase Enzyme was first discovered from the malt infusion. Anselme Payen and Jean Francois Persoz originally pioneered the existence of the diastase enzyme in the year 1833. Malt diastase, amylase etc., are the alternatives names for the diastase.

It is used as a substitute for an enzyme (amylase). Malt, barley seeds, plants, milk, saliva etc., are the sources of diastase enzyme. Diastase makes the most out of the food it consumes. In this context, we will discuss the meaning, enzymatic activity, properties and uses of the diastase enzyme.

Content: Diastase Enzyme

Diastase Enzyme Meaning

It refers to the digestive enzyme in plants whose activity can be compared with the role of amylase in human digestion. Diastase splits the starch into malt sugar, and the amylase in human saliva breaks down the complex carbohydrates into simple sugar (glucose). Nowadays, diastase is also called a group of amylases (α, β and γ), which splits starch in the following expression:

A-B + H2O = A-OH + B-H

Diastase Enzyme Activity

We can conduct a series of experiments to know the effect of diastase activity in germinating seeds effect at different temperatures and pH.

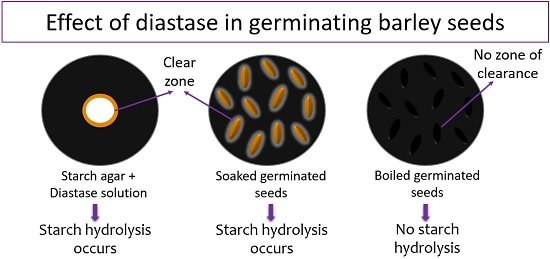

Diastase Activity in Germinating Seeds

Step-1: First, prepare starch agar media and pour the molten media into the three sterilized Petri plates. Add 1 ml of diastase solution and leave it for some time. Flood the prepared plate with iodine solution. Then, you would observe a zone of clearance in the starch agar media by the diastase enzymatic activity. This indicates the occurrence of starch hydrolysis, and the halo zone indicates the formation of maltose.

Step-2: Then, soak the germinated barley seeds in water overnight. Strain the soaked barley seeds, put them over the second plate of starch agar media, and leave it for some time. Flood the prepared plate with iodine solution. You would observe a zone of clearance in the starch agar media by the diastase enzyme present within the cells of germinated barley seeds. This indicates the occurrence of starch hydrolysis, and the halo zone around the germinated barley seeds indicates maltose formation.

Step-3: Boil the germinated barley seeds and strain out the water. Then, put boiled barley seeds over the third plate of starch agar media and leave it for some time. Flood the prepared plate with iodine solution. Here, you would not observe a zone of clearance in the starch agar media due to the diastase enzyme’s deactivation resulting after the boiling of germinated barley seeds. It indicates that the starch hydrolysis would not occur in the absence of a diastase enzyme, and thereby there will be no formation of a clear or halo zone.

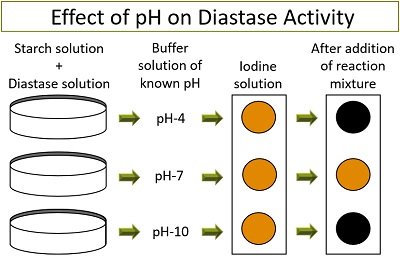

Effect of pH on the Activity of Diastase

Step-1: Take three Petri plates and add buffer tablets of known pH (4, 7 and 10). Then, add 5 ml of starch solution to each plate, followed by adding 1 ml of diastase solution. Shake the contents of the reaction mixture vigorously.

Step-2: Take a spotting tile and add 1 ml of iodine solution. After every five minutes, you need to add 1 ml of the reaction mixture into the spotting tile’s depressions contained iodine solution by using a micropipette.

Step-3: Observe the plates and note the time for the complete disappearance of the iodine colour. Then, plot a graph between the time taken for the starch hydrolysis and the effect of pH. You would observe the time taken for the complete hydrolysis of starch will differ at different pH.

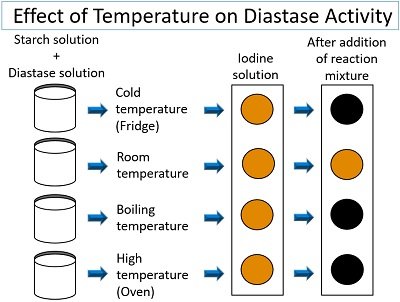

Effect of Temperature on the Diastase Activity

Step-1: Pour 5 ml of the starch solution into the four small beakers. After that, add 1ml of diastase solution into all the beakers using a micropipette and keep them at varying temperature (like fridge, room temperature, boiling water bath and oven). Wait for some time to test the starch hydrolysis by using an iodine reagent.

Step-2: Add a drop of the reaction mixture to the spotting tile that already contained 1 ml of iodine solution. Starch in reaction with iodine forms a blue-black coloured complex, whereas maltose does not react with iodine. Therefore, maltose formation or starch hydrolysis is confirmed by the disappearance of the blue-black colour or the formation of clear zones.

Step-3: You need to plot a graph between the times at which the starch hydrolyzes completely against a different range of temperature.

Properties of Diastase Enzyme

- The optimum pH for the diastase enzyme is 6-7.

- The optimum temperature for the diastase enzyme is between 35-40 degrees Celsius.

- Diastase is thermolabile, i.e. denatures at a temperature above 45 degrees.

- Diastase activity gets deactivated at an acidic pH upto 4.

- It is naturally obtained from malt extract.

- It forms a precipitate on reaction with alcohol and ether.

- Diastase exists as a white amorphous powder in a solid-state and exists as amber to a dark brown solution in a liquid state.

- It is incompatible with strong oxidizing agents.

- It helps in the digestion of starchy foods like potatoes, grains etc.

- Milk, honey and germinated barley seeds are the natural sources of diastase enzyme. Diastase is also available as a food supplement in the form of tablets, powder and capsules.

Uses

Glucoamylase and amylase are the enzymes present in human saliva that convert complex carbohydrates into simple sugars and necessary for digestion. Some people don’t produce enough salivary amylases and face digestion problems.

Diastase serves as a substitute for amylase, which can efficiently help in the digestion of food like grains and vegetables. As the age increases, diastase production falls down, and people may experience acid reflux, indigestion, bloating and upset stomach.

Therefore, diastase aids digestion and other gastric functions and serves as a digestant to treat clinical conditions like indigestion and pancreatitis. It is also used in the production of pre-digested starch food in the fermentation and brewing industry.