Biofertilizer production is necessary for the agricultural lands that have been deprived of soil minerals and nutrients essential for plant growth and development. Thus, soil minerals are required for the plant’s growth. But, due to the excessive burden on agricultural land by the increasing population, the land area for farming is limited.

Thus, it becomes necessary to utilize the agricultural lands economically to obtain the maximum yield. Nitrogen is a major element important for plant growth. The demand for nitrogen is generally fulfilled by employing chemical fertilizers, though they impose serious health hazards and reduce soil fertility.

However, the use of biofertilizers that contain living microorganisms increases crop yield by improving soil fertility. Biofertilizers are different from chemical fertilizers that negatively impact the soil quality and the people consuming those crops.

Besides, chemical fertilizers are quite expensive, and cost production is also high. Thus, biofertilizers are recommended over chemical fertilizers as they improve the soil structure and texture and enrich the soil with essential nutrients required for plant growth. This post describes the definition, purpose and steps involved in biofertilizer production.

Content: Biofertilizer Production

Definition of Biofertilizer

Biofertilizer is the formulation of living microbes that fix the atmospheric nitrogen either by living freely in the soil or by associating symbiotically with the plant. Its commercial production is cost-effective and relatively inexpensive to buy.

It enriches the soil with dormant (metabolically inactive) or living microorganisms that neither degrade the soil quality nor harm the growing plants. Biofertilizers are easily biodegradable products that do not cause soil pollution. The organisms that are prevalently used in the bio-inoculant preparation are:

- Nitrogen-fixing soil bacteria (Azotobacter and Rhizobium species)

- Nitrogen-fixing cyanobacteria (Anabaena species)

- Phosphate-solubilizing bacteria (Pseudomonas species)

- AM fungi

Biofertilizers significantly enhance the microbial process to increase the bioavailability of nutrients in the forms that the plants can assimilate. Biofertilizers have a low cost and play an essential role in supporting soil health and minimizing environmental pollution.

Purpose

A plant requires a balanced amount of nutrients and minerals to grow. It will be shocking to know that only a small portion of soil produces nutrients through biological or chemical methods every year.

Therefore, biofertilizer production aims to supplement the soil with the essential nutrients that already exists in it. It also aims to control soil-borne diseases. The production and use of biofertilizers aim to improve soil health and soil properties and result in higher yield rates.

Production

Biofertilizers are the biological preparations with live dormant strains of microbes, which positively impact soil rhizosphere and helps in plant development. Biofertilizers are formulated with living or dormant (inactive metabolically) microbial cells. An efficient nitrogen-fixing strain is selected, and later the inoculum is prepared to produce a bio-fertilizer of good quality.

An inoculum is a form in which the strain is inoculated in the seed or soil. Besides strain selection, maintenance, storage and packing are other aspects of bio-fertilizer production. During the biofertilizer production, the product manufactured must fulfil the quality standards laid down by BIS.

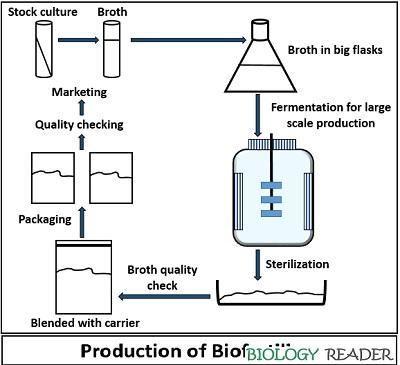

Commercial Production: To produce inoculum, you must inoculate the isolated strain in small flasks containing a suitable medium. The starter culture should have a volume that must produce at least 1×109 cells/ml. Then, add culture to the carrier for the preparation of bio-inoculant.

Carriers carry nitrogen-fixing organisms. Primarily, sterilize the carrier and then inoculate it into the seed or soil. But in a few cases, the carrier is inoculated first and later subjected to sterilization via UV irradiation. Then, package the inoculum or biofertilizer with a standard quantity of 109-1010 viable cells/gram.

As per the quality standards, the final moisture content of the biofertilizer must be 40-60%. For large scale biofertilizer production, use large culture fermenters rather than big flasks. The production process of biofertilizer includes the following sequential steps:

Strain Selection

First, select the efficient nitrogen-fixing strains and later maintain the culture of strains artificially in the laboratory on the nutrient-rich medium before inoculating them in the seed or soil.

Seed Pelleting

Then, prepare the inoculum of the desired strain. After that, inoculate the seeds using either of the seed coating methods (direct coating or slurry method). The direct seed coating method uses gum arable or sugary syrup. The slurry seed coating method uses efficient nitrogen-fixing strains (coating of rhizobia over specific host legume seeds).

Then, add calcium carbonate to the sticky seeds right away after seed coating. Sometimes, root nodule bacteria are absent in soil, necessary to fulfil the plant’s nitrogen requirements. Therefore, we should inoculate the soil with inadequate nodule bacteria with seed pellets of highly effective rhizobia.

Inoculant Carriers

Inoculants are simply the mixture of the starter culture and a finely milled carrier material. The ideal properties of the carrier should have the properties:

- Non-toxicity

- Good moisture absorption capacity

- Free of lump forming material

- Easy to sterilize

- Inexpensive

- Easily available

- Good buffering capacity

Therefore, the carrier material with these properties can prolong the growth of microbial strains. Peat is the most standard carrier used in bioinoculant preparation. The application of peat is not common in few countries such as India due to its unavailability.

Therefore, peat as a carrier can be substituted with various alternative carriers like lignite, coal, charcoal, vermiculite, polyacrylamide etc. The production of inoculant involves carrier processing, in which the carrier material is subjected to the following stages:

- Mining: Carrier like peat is mined, drained and cleared off stones, roots, etc.

- Drying: Then, the carrier material is shredded and dried.

- Milling: After that, pass the peat through heavy mills. Peat is generally used as a soil inoculant, with a preferable particle size (0.5-1.5 mm).

- Neutralization: Then, neutralize the carriers by treating them with precipitated CaCO3, which maintains the pH between 6.5 and 7.0.

- Sterilization: At last, sterilize the carriers so that they can be used as inoculants.

Quality Standards for Inoculants

During the production of biofertilizers, it should be kept in mind that the product must make up the quality standards. The inoculant should be carrier-based. There should be a minimum of 108 viable cells per gram (dry mass) of the carrier in the inoculant. The inoculant must have an expiry period of at least 12 months from DOM.

Packaging

Finally, pack the bio-inoculant in polyethene bags of low density (50-75 µ). Label each packet with the product information like name of the product, type of carrier, batch number, DOM, DOE, net quantity and storage instructions etc. Each packet should be ISI (BIS) certified.

Storage

Store the bio-inoculant in a cool and dry place. Keep the bio-inoculant ideally at a temperature of 15°C and a pH between 6.0 and 7.5.

Inoculation into the Field

Seed inoculation and soil inoculation are the two standard inoculation methods that are prevalently used. The soil inoculation involves direct mixing of the bio-inoculant into the sowing furrow along with the seeds. Seed inoculation is a more popular technique that involves seed pelleting or coating with an inoculant.

Your site has intrigued me to study more of your contents.