The continuous culture is an open cultivation process, in which the cell growth is maintained in the continuous mode of operations. It works as an open cultivation system, in which the fresh nutrient medium is continuously added into the culture vessel rather than recycling and reuse of the nutrients or substrate.

There is an inlet pump in a continuous cultivation system that continuously allows the sterile nutrient medium to enter the reservoir. An effluent pump continuously elutes the excess cells and by-products of the medium.

By this continuous operation, the microbial cells grow in a steady exponential phase, as there is neither depletion of nutrient nor accumulation of toxic by-products. In continuous culture, cell density and other factors like the concentration of a substrate and product remains constant, whereas the addition of fresh nutrient medium dilutes the culture medium.

The increase in the fresh nutrient medium’s flow rate will increase the dilution rate and decrease retention time. In this session, we will understand the definition, apparatus used, drawbacks and advantages of the continuous culture.

Content: Continuous Culture

Definition of Continuous Culture

Continuous culture is one of the cultural processes, in which the bacterial population grow at a constant cell concentration and volume within the culture vessel or reservoir. It is a type of open cultivation system. As the name itself defines that there will be the continuous addition of the nutrient medium and the constant elution of the product. This property of a continuous culture differentiates it from the batch and fed-batch culture methods.

In the continuous culture, the growth rate of microbial cells is maintained in the exponential phase, i.e. the cells could not reach the stationary phase of growth. The process of maintaining the microbial cells in the log or exponential phase refers to the steady-state of growth.

Apparatus for Continuous Culture

One requires some additional equipment to maintain the microbial cells’ steady phase to perform the continuous culture method. Chemostat and turbidostat are the two unique types of equipment, which are most commonly used in continuous culture.

Chemostat

It is an apparatus used for the continuous culture of bacteria where the cell density is kept constant by keeping the dilution rate and flow rate of nutrient medium constant. Chemostat was introduced in the 1950s by three scientists Monod, Novick and Szilard. The sterile nutrient medium is added into the reservoir along with the microbial cells. The dilution rate controls the concentration of the nutrient medium.

In a chemostat, the substrate is continuously added into the reservoir, and the by-products are continuously eluted from the reservoir. The bacterial cells will grow at a constant rate, i.e. the exponential phase because there will be no nutrient depletion due to continuous nutrient supply into the reservoir. The chemostat depends upon the two factors like:

- Dilution rate

- The concentration of limiting nutrient

Dilution rate: The dilution rate is the flow of the nutrient medium into the reservoir by the culture volume within the vessel. The change in dilution rate will change the growth rate of bacteria, i.e. both cell growth and cell density. Cell density remains constant in case of constant dilution or the flow rate of the medium. If the dilution rate alters, cell density and cell growth will also change.

The limiting nutrient concentration: In Chemostat, an essential nutrient or amino acid is added in limited quantity. By limiting the concentration of an essential nutrient, one can determine the nutrient medium’s flow rate into the reservoir. Therefore, this essential nutrient will also determine the bacteria’s growth rate, i.e. whether the cell density is constant or not. If the concentration of the limiting nutrient alters, the cell density will also change.

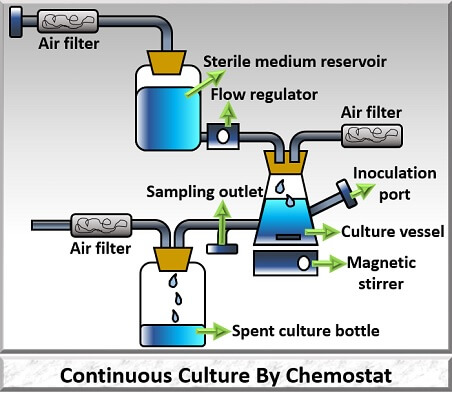

Culture of Bacteria by Chemostat

To perform the continuous culture by the chemostat, there are three elements like substrate reservoir, culture vessel and the spent culture bottle. The sterile nutrient medium is continuously added into the culture vessel via flow regulator. The flow regulator allows the constant flow of the fresh substrate into the culture vessel.

There is an inoculation port in the culture vessel, from which the inoculum of bacteria is added. Apart from inoculation port, a culture vessel comprises magnetic stirrer at the bottom, allowing uniform mixing of the cells within the nutrient medium. The remaining dead cells and the by-products from the culture vessel are released from the sampling outlet into the spent culture bottle.

Turbidostat

It is also called “Biostat”. A turbidostat is a device that maintains the constant cell density by controlling the flow rate of the fresh medium. Turbidostat is an apparatus introduced by the two scientists Bryson and Szybalski in the year 1952. It is a device, which working depends upon the two components like:

- Photoelectric device

- Optical sensing device

Photoelectric device: A photoelectric device like photodiode performs a key role in examining the cell density in the culture vessel. Therefore, it determines the alternation in the concentration of the medium.

Optical sensing device: An optical sensing device plays a pivotal role to measure the turbidity or absorbance of the culture in the reservoir. Turbidostat uses a turbidometer, which helps to find out the optical density of the medium. A turbidostat monitors the flow rate or the dilution rate vigorously to make the turbidity constant.

Culture of Bacteria by Turbidostat

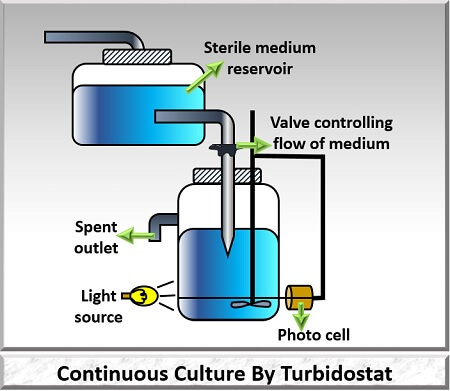

A turbidostat is an apparatus which includes a sterile reservoir, culture vessel, photocell and a light source. In turbidostat, the fresh nutrient medium is automatically regulated, which maintains the predetermined turbidity. The fresh nutrient medium is added to the culture vessel through a valve, which controls the flow of the medium.

The fresh nutrient medium is added once the optical density increases. The cell density is kept constant is the culture vessel by the help of a photoelectric device. The photoelectric device measures the turbidity of the medium by absorbing the light source. The turbidity is monitored throughout the process.

Drawbacks

- There is a high risk of contamination, as the process continues without cleaning and proper sterilization.

- To carry out the process of continuous culture, high technical skills are required to maintain the bacterial cells’ steady-state.

- To perform a continuous culture, it requires some additional and specific equipment.

Advantages

- The process is cost-effective.

- As there is continuous processing, it reduces the number of stages like cleaning, sterilization, preparation of starter cultures etc.

- In continuous culture, the cell population can be maintained in the exponential phase at constant cell concentration for a long time.

- By reducing the number of stages, it also saves time and energy.

- As the product is continuously eluted, the secondary metabolites’ toxicity does not affect the culture medium. Therefore, continuous culture avoids the accumulation of toxic substance.

- It gives high productivity by utilizing the substrate.

Conclusion

The continuous culture requires two apparatus like chemostat and turbidostat to maintain a cell in a steady phase of growth. Both chemostat and turbidostat follow some similar criteria like:

- Maintenance of the constant cell density.

- Growth of microbial cells in steady-state.

- The flow rate of the medium and the cells are continuously changing.

Therefore, a continuous culture is preferred over other cells cultivation methods like batch and fed-batch culture. It gives high productivity as the microbial cell exists in their logarithmic phase. The log phase is a stage of highest metabolic activity where cells convert substrates into a product.