Trickling filter process is one of the types of aerobic wastewater treatment. It is a fixed-bed bioreactor that is the part of secondary wastewater treatment, which eliminates the coarse particles, suspended organic and inorganic waste, small colloids etc. out of the primary effluent. A trickling filter is also called biological filter, as it makes the use of active microbial mass as a bioweapon to degrade the waste out of primary sewage.

Unlike activated sludge treatment, the trickling filter follows an attached growth system inspite of suspended growth system. In this article, we will highlight the design or construction, operation, types, advantages and disadvantages of the trickling filter.

Content: Trickling Filter Process

Definition of Trickling Filter Process

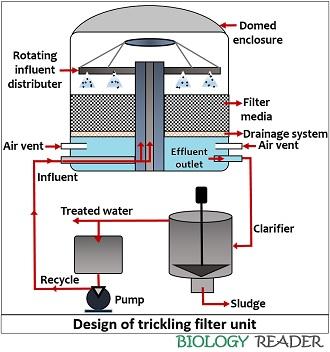

Trickling filter process can define as the biological system, which tends to separate or degrade the maximum organic and inorganic waste (up to 85%) out of the primary or raw sludge via the slime layer. The designing of a trickling filter unit includes a support structure, pebble or plastic filled media and rotary distributor.

It works under the aerobic conditions and makes the use of aerobic microbes so that they can exploit or oxidize the organic matter into a simpler form. The filter bed is placed below the pebble filled media, which aids the separation of secondary effluent out of waste activated sludge. The final effluent is released from the outlet pipe and further treated with disinfectants like chlorine, UV, ozone etc. to make it safe for disposal.

Operation

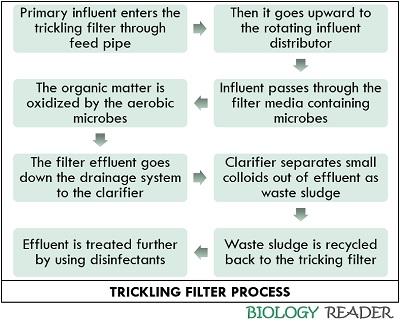

The trickling filter process goes through a series of operation, which involves the following stages:

Introduction of the settled sewage

The raw or primary sewage from the primary clarifier tank enters the trickling filter tank at a steady rate. The sewage must be primarily treated via a series of operations like screening, grit removal and primary clarifiers to prevent clogging in the trickling filter system. Primary influent that enter the trickling filter unit is free from coarse objects, suspended solids, rags etc. A dosing device (tipping bucket) is a piece of equipment allowing the supernatant to flow upwards to the arms of the perforated rotary distributor.

Sewage flushing

The primary sewage flushes downward via a perforated rotary distributor, which evenly distribute the sewage over the filter matrix. The filter bed is packed with constituents like rock, gravel, redwood, synthetic material etc. that acts as a media for the attachment of the microorganisms. Therefore, the trickling filter is the best example of an attached growth system, in which biomass is directly associated with the media instead of sewage suspension.

Passage through the filter media

The filter media is chiefly composed of porous media that increases the surface area for the decomposition of the organic matter by the microorganisms. Trickling filters are generally available as the standard rate and high rate filter, in which both have different hydraulic and organic loading rate. It is also provided with air vents and backwashing to avoid odour, fly breeding and to clog problems.

Pollutant degradation

The microorganisms attached to the filter bed utilize organic waste as a food material. The pollutants like organic and inorganic waste in the sewage suspension go through the absorption and adsorption into and over the filter bed by the microbial slime layer.

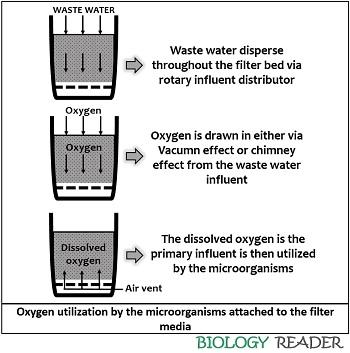

Oxygen utilization by the microorganisms

The treated primary sewage splashes through the arm of a rotary distributor provide the oxygen supply in the form of dissolved oxygen. Oxygen is drawn into the filter media via vacuum or chimney effect. The bio-film layer uses the dissolved oxygen trapped within the filter media and oxidize the organic compounds by releasing carbon dioxide gas, water and other oxidized end products.

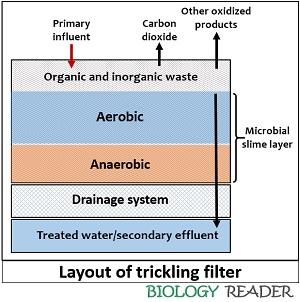

Slime layer

It also refers as a slime layer, which contains aerobic biomass of the surface of the filter bed up to the thickness of 0.1-0.2mm. In contrast, the remaining area contains anaerobic biomass. The above surface containing aerobic microbes is considered as the rapid growth phase region, as the microorganisms harness direct sunlight and maximum amount of oxygen to degrade the organic waste.

In contrast, the lower surface containing anaerobic microorganisms is considered as the oxygen-deficient region, in which the microbes enter the endogenous phase to utilize their own cell for the growth. After a certain point, the biofilm layer thickens gradually by the organic matter decomposition, and later it sloughs off into the liquid flow and further separated inside the clarifier or sedimentation tank out of effluent.

Design

Trickling filter functions as a bioreactor in the secondary wastewater treatment, and its layout includes the following:

Filter bed: It is a bed chiefly containing crushed rock or other coarse media. The construction of a filter bed is roughly 6 feet deep and 200 feet in thickness. Settled sewage is flushed evenly over the filter bed containing organic and inorganic waste via continuously rotating distributor’s arm. Holes within the rotary distributor arm facilitates the trickling of primary influent and settled sewage throughout the filter bed.

Microbial film: Within the filter media some aerobic microbes are found on the surface, and some anaerobic microorganisms are found below the filter media. As the wastewater trickles downward, the microorganisms associated with the filter media starts utilizing the organic matter of the wastewater and forms a later called microbial slime. Thus, the microorganisms in the filter media play a pivotal role in degrading the organic matter in the sewage, thereby minimizes BOD and COD from the sewage.

Drainage system: The treated wastewater from the trickling filter bed goes down the drainage system and further undergoes tertiary treatment via membrane filter and disinfection before secondary sedimentation. A secondary clarifier is a sedimentation unit, which separates the small colloids, suspended particles etc. at the bottom out of waste fluid.

Besides, the tertiary treatment is also necessary for the safe disposal of the effluent, as this step eliminates the pathogenic microorganisms. In contrast, the oxidized or decomposed organic matter sloughed down and recycled back in the trickling filter mediated via return pump.

Types of Trickling Filters

Depending upon the hydraulic and organic shock load, trickling filters can be categorized into two types, namely high rate and low rate trickling filter. The hydraulic loading rate can define as the sewage flow (Q) per unit volume (V) of filter bed in a day, while the organic loading rate can define as the kilograms of BOD (Y5) introduced into the per unit volume (V) in a day.

- The BOD removal efficiency of both standard and high rate trickling filter is about 75 to 90%. The nitrification of the primary effluent is relatively higher in low rate filters, whereas high rate trickling filters produce partially nitrified effluent.

- Low rate and high rate trickling filter are suitable for the treatment of low to high strength domestic wastewaters and industrial wastewater.

- Recirculation of the effluent is not provided in the low rate filters. In contrast, high rate filters are provided with return pump between the trickling filter tank and secondary clarifier that aids in effluent recirculation.

To identify the characteristic difference between the two, one can look upon the table given below that specifies the efficiency and depth of the low and high rate trickling filter.

| Properties | Low rate trickling filter | High rate trickling filter |

|---|---|---|

| Hydraulic loading | 1-4 m3/m2.d | 10-40 m3/m2.d |

| Organic loading | 0.08-0.32 kg BOD/m3.d | 0.32-1.0 kg BOD/m3.d |

| Depth | 1.8-3.0 m | 0.9-2.5 m |

| Recirculation ratio | 0 | 0.5-3.0- domestic wastewater 8- strong industrial wastewater |

Advantages

- It is a simple and reliable secondary treatment unit of the wastewater.

- It can be used to degrade a variety of organic waste.

- Trickling filter can resist shock loadings.

- It efficiently oxidizes the ammonia or efficient in ammonium oxidation.

- Trickling filter aids to produce effluent free of BOD, COD, nutrients, suspended colloids etc.

- Its construction requires a small land area, unlike constructed wetlands.

Disadvantages

- Its designing requires high capital costs.

- The designing of a trickling filter requires expert skills.

- Its operation and maintenance require regular attention by the skilled labour personnel.

- The trickling filter process is a continuous process, which needs an uninterrupted supply of electricity and wastewater distribution.

- It sometimes causes flies breeding and odour problem.

- The effluent produced by the trickling filter needs to treated further by the chemical disinfectants.

- Accumulation of excessive biomass may cause clogging of the TF-unit.

- Not all parts and materials may be locally available.

Conclusion

Therefore, we can conclude that the trickling filter process is one of the attached growth system, which means that the microorganisms responsible for the degradation of the organic matter are attached to the non-submerged packing material. It is designed for the secondary treatment of the primary influent to eliminate the suspended and soluble organic waste along with the nutrients.

Wish, I had found this earlier.