The production of penicillin is practised commercially to treat various infections caused by gram-positive aerobic bacteria. Penicillin is a narrow-spectrum antibiotic or effective against many gram-positive bacteria, especially Streptococcus and Staphylococcus species.

There are approximately 100 penicillins synthesized so far. For penicillin production, different strains of Penicillium (Penicillium notatum or Penicillium chrysogenum) are used. P. chrysogenum improves the yield of penicillin (50 g/dm3).

In this post, you will get a quick overview of penicillin production and the meaning, properties and history of penicillin. In addition, we will also study the overall steps in the industrial production of penicillin as well as the uses of penicillin.

Content: Production of Penicillin

Overview of Penicillin Production

Penicillin production is an industrial process that commercially produces penicillin by using a fungal strain (P. chrysogenum) and the feedstock containing desired N-source, C-source, and minerals etc.

It uses the fed-batch culture method. Penicillin is produced as a secondary metabolite by using living microorganisms, which is then recovered from the feedstock solution. Its production is medically important to cure infections caused by the gram-positive Staphylococci and Streptococci species.

The penicillin inhibits the bacterial activity by inactivating the penicillin-binding proteins inside the cell wall and finally destroys the cell wall synthesis of such bacteria.

What is Penicillin?

It refers to one most important antibiotics, which requires fungal strains (Penicillium notatum or Penicillium chrysogenum). It acts as a cell wall destroyer of bacteria. Penicillin originated from the Latin word Penicillium, which means “a painter’s brush” as the fronds of fungus were looked like a painter’s brush.

Nowadays, many derivatives of penicillin are available to kill the majority of bacteria than penicillin. Although, it is useful in killing different types of bacteria like Streptococcus pneumoniae, Listeria species, etc.

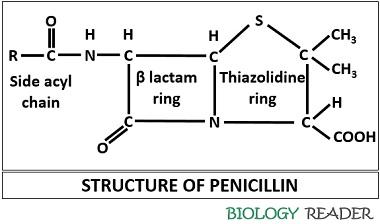

The structure of penicillin differs in a side chain that is linked to the amino group. In this post, we will focus on the structure of penicillin G, which consists of a side acyl chain, β lactam ring and thiazolidine ring.

The β lactam ring is responsible for antimicrobial activity and useful to destroy the cell wall synthesis of gram-positive bacteria, especially Staphylococcus and Streptococcus species.

Properties of Penicillin G

Penicillin G serves as a secondary metabolite, which generally forms during the stationary phase. Below, you can see some of the physical and chemical properties of penicillin G.

Chemical Properties

- Molecular Formula: C16H18N2O4S

- Molecular weight: 334.4 g/mol

- Formal charge: Zero

- Density: 1.41

- Solubility: It is insoluble in petroleum ether, sparingly soluble in water and readily soluble in organic solvents like methanol, ethanol, benzene etc.

Physical Properties

- Physical state: Solid

- Colour: Amorphous white powder

- Odour: Odourless

- Melting point: 214-217 degrees Celsius

History

A scientist named Alexander Fleming (Professor of Bacteriology) introduced penicillin in the year 1928. Once, he cleaned his messy lab and observed that the Petri dishes cultured with Staphylococcus bacteria were contaminated with mould.

That mould was named Penicillium notatum that preventing the growth of bacteria. Fleming called “penicillin”, an active agent of Penicillium notatum, which destroys the different bacterial species.

Industrial Production of Penicillin

Most of the antibiotics follow the same method for commercial production. Majorly, the difference in the production process lies in the following three factors:

- Microorganisms used

- The composition of media

- A procedure used in extraction.

The industrial production of penicillin includes the following steps:

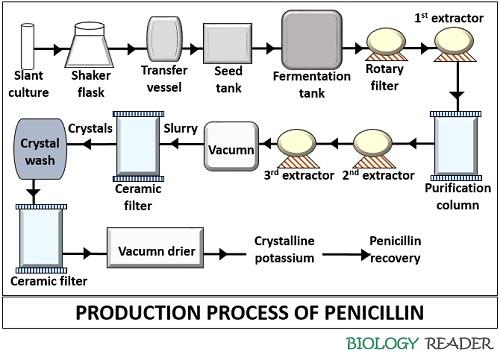

Inoculum Preparation

Preserve the culture of P. chrysogenum strain as a lyophilized spore. Firstly, culture the P. chrysogenum into a flask for seven days at a temperature of 24 degree Celsius with a wheat bran nutrient solution. After this phase, we can get a high yield strain of P. chrysogenum.

Transfer of Inoculum

Now to support mycelial growth, shift the prepared culture to the inoculum or seed tank. Then, keep the prepared culture under proper aeration and agitation, and leave it to grow for 1-2 days. This stage is generally known as the “Growth phase of mould“.

Fermentation

Add inoculum into a fermentor filled with production medium or feedstock solution containing the following constituents:

- 10% total C6H12O6 (glucose)/molasses

- 4-5% corn-steep liquor solids

- 0.5-0.8% C8H8O2 (phenylacetic acid)

- 0.5% vegetable oil.

Then, set the pH to 6.0 and temperature between 25-26 degree Celsius. The fermentation process requires aerobic conditions. For adequate nutrient supply, you need to maintain regular feeding in a fed-batch culture system.

The fermentation process requires one week for penicillin production. Initially, the mycelial growth utilizes the available carbohydrates, thereby reducing the carbohydrate level in the culture medium.

Because of the reduced carbohydrate level, penicillin production begins from the 2nd day of fermentation. Then, by the end of the 7th day, the pH of the medium rises to 8.0, and the production of penicillin stops.

Filtration

The production of Penicillin G increases due to the presence of the precursor. Here, phenylacetic acid acts as a precursor for the benzene ring’s side chain of Penicillin G.

We can use the fungal biomass as a feed supplement for the animals by the end of the fermentation period, for which you need to separate the fungal biomass via filtration.

Extraction

Extract penicillin G from the broth by using organic solvents. After purification, we obtain penicillin G as a potassium salt, which later transforms into 6-aminopenicillins acid (6-APA). Industrialists can produce different derivatives of penicillin by modifying the side chain of 6-APA.

Uses of Penicillin

- Penicillin V potassium treats different kinds of infections like pneumonia, respiratory tract and throat infections.

- Penicillin V potassium prevents rheumatic fever.

- Sometimes, penicillin also cures anthrax infections on the skin.

- In combination with other antibiotics, it can also treat diphtheria.

- Penicillin V potassium also treats heart valve infections.

Conclusion

Therefore, penicillin production is a vital process in medical biology, as it functions as an antibiotic that inhibits bacterial activity or infections caused by various gram-positive microorganisms.

A very Good article, simple and easy to understand, Thank you.