Biohydrogen is now commercially produced as a biofuel. It is the advanced biofuel, which makes the use of living biomass or organisms for the production. Biohydrogen is now considered best among all the biofuels as it accounts to fulfil all the energy demands as it can be obtained from the sustainable resources like:

- Biological splitting of the water molecules

- By the conversion of biomass

- By the solar thermal splitting of water

Biohydrogen is a type of other biofuels like bioethanol, biodiesel, and bio-oil etc. Hydrogen can be generated by both chemical and biological method. Therefore, a method from which hydrogen is produced biologically (by using microorganisms) in a bioreactor will be termed as biohydrogen. In simple words, we can say the biological conversion of hydrogen into biohydrogen via microorganisms is known as biohydrogen.

Content: Biohydrogen

- Definition of Biohydrogen

- Milestones in the Discovery of Biohydrogen

- Generations of Biofuels

- Ideal Properties of Hydrogen as a Biofuel

- Limitations of Biohydrogen

- Production of Biohydrogen

- Factors Affecting Biohydrogen Production

- Future Prospects of Biohydrogen

Meaning of Biohydrogen

Biohydrogen is defined as the biofuel or the source of energy that uses living microorganisms to convert hydrogen via biological processes like fermentation and photolysis in a specialized container or a bioreactor.

Milestones in the Discovery of Biohydrogen

| Year | Scientists | Discovery |

|---|---|---|

| 1939 | Hans Gaffron | Discovered the switching of algae between the production of H2 and O2 |

| 1997 | Ananstasios Malis | Discovered the cause of algae to switch from producing H2 by the depletion of sulphur |

| 2006 | Researchers from the University of Bielefeld | Discovered large amount of hydrogen by genetically modifying the single cell Chlamydomonas reinhardtiin |

| 2007 | Ananstasios Malis | Discovered the conversion of solar energy to chemical energy in tax X mutants of Chlamydomonas reinhardtiin |

Generations of Biofuels

There are three generations of biofuel, which include:

- Biofuels made from a food crop, and their residues are termed as “First-generation biofuels”.

- Biofuels made from non-food crops or wastes are termed as “Second-generation biofuels”.

- And the biofuels made by the use of microorganisms are termed “Third-generation biofuels” or “Advanced biofuels”.

Among these three generations of biofuel, biohydrogen comes in the category of third-generation biofuel or advanced biofuel. Third-generation biofuel has certain advantages over the first and second-generation biofuel. The production of the first-generation biofuel has increased the price rates of the food items. Second-generation biofuels have required more surface area or land for the production of the biofuel. In contrast, advanced biofuel requires smaller areas for the production and can capture solar energy 10 times to that of the second generation.

Ideal Properties of Hydrogen as a Biofuel

In everyone’s mind, there will be a question, that why hydrogen? So, we will discuss some ideal properties of hydrogen, that why it is used as a “biofuel”. There are some unique properties of hydrogen, which makes it ideal for the production as a biofuel:

- Hydrogen has three times the high energy density than petrol and diesel.

- Hydrogen is highly combustible fuel.

- Combustion of hydrogen only yields water, which does not contribute to the gaseous pollutants.

- The efficiency of providing energy is more, with its little use.

- Acts as an energy carrier as it can trap sunlight, wind, water as a renewable source.

- Hydrogen can be used as a transport fuel, by storing it as a metal hydride.

- It can be easily produced by the renewable source of energy like solar, wind, water etc.

Limitations of Biohydrogen

- Storage of hydrogen is difficult.

- There is a limitation of the cost in the competitive technology for the production of biofuel.

- The utilization of hydrogen is quite difficult.

- Hydrogen readily escapes from the atmosphere to space.

Production of Biohydrogen

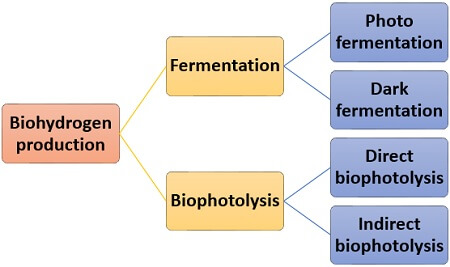

Fermentation and biophotolysis are the two popular methods used in biohydrogen production.

- Production through fermentation: It involves two methods, namely photo fermentation and dark fermentation.

- Production through biophotolysis: It also involves two methods, namely direct and indirect photolysis.

Through Fermentation

The fermentation of Biohydrogen is carried out by the use of microorganisms like bacteria. The process is either carried out in the presence of light, i.e. photo fermentation or in the absence of light, i.e. dark fermentation.

Photofermentation

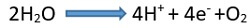

This process makes the use of photosynthetic organisms and the additional light source. The organisms used in the photo fermentation carry out photosynthesis by using photosystem-I only for the production of hydrogen. For the splitting of water, these organisms require an additional light source and utilize organic acids like acetic acid to generate hydrogen by donating its electron.

![]()

In the above equation, we can see that there is no evolution of oxygen or indicates the anoxygenic photosynthesis.

Dark Fermentation

It is a process which makes the use of carbohydrate as an energy or carbon source. Dark fermentation does not require a source of light energy. Other than carbohydrate (like glucose), it can also use other substrates like organic compounds, polymers (starch, cellulose etc.), and algal biomass etc. Dark fermentation is a very complex process to carry out, which requires a series of biochemical reactions.

- Breakdown of glucose into pyruvate and NADH: During this step, glucose converts into pyruvate by the phosphorylation of NAD into NADH.

- Conversion of pyruvate to acetyl CoA: The conversion of pyruvate into acetyl CoA can be catalysed by the use of two enzymes.

- Catalysis by ferredoxin oxidoreductase

- Catalysis by formate lyase

- Catalysis by ferredoxin oxidoreductase

- Reoxidation of ferredoxin: This step involves the reoxidation of ferredoxin by the Fe-fe hydrogenase enzyme.

- Production of hydrogen

Biophotolysis

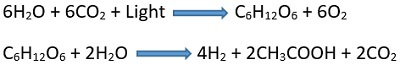

It makes the use of photoautotrophic organisms such as microalgae and cyanobacteria. These organisms use light as an energy source and carbon dioxide as a carbon source for the splitting of hydrogen. Therefore, the production process of biohydrogen in biophotolysis is carried under anaerobic conditions.

![]()

Direct Photolysis

It makes the use of solar light as a light source and photosynthetic algae to convert water into chemical energy or to produce hydrogen.

Direct photolysis involves two steps for the generation of biohydrogen:

- Absorption of sunlight by the photosystem-II of algae leads to the oxidation of water into electrons, protons, and oxygen molecules.

- Absorption of sunlight by the photosystem-I of algae leads to the transfer of an electron to the ferredoxin and to the hydrogenase enzyme through the electron transport chain. Recombination of proton and electron generates hydrogen gas.

This process is also called one stage photolysis, in which the hydrogen can be produced directly by the use of water, light energy and algae photosystem.

Indirect Photolysis

This process makes the use of photosynthetic microorganisms like microalgae, and cyanobacteria etc. Indirect photolysis also converts solar energy into the chemical energy by the series of two steps. In the first step, there is the production of biomass by the photosynthetic system. The second step involves the utilization of the biomass rich in carbohydrates to produce biohydrogen.

Indirect photolysis involves the removal of both hydrogen and oxygen at different steps during the process to avoid the sensitivity of the hydrogenase enzyme. It involves two stages to complete a reaction, so it is also called two-stage photolysis. Cyanobacteria used in the process of indirect photolysis are Gloebacter sp and Synechocystic sp etc.

Table showing different biological processes for the production of biohydrogen:

| Biological processes for the production of hydrogen | Organisms used | Yield of hydrogen | End product |

|---|---|---|---|

| Photo fermentation | Phototrophic bacteria like purple sulfur and non-sulfur bacteria | 0.16 | H2 and CO2 |

| Dark fermentation | Fermentative bacteria like Clostridium, Citrobacter and Enterobacter sp. | 65-75 | H2 , CO2 and VFA |

| Direct photolysis | Green algae | 0.07 | H2 and O2 |

| Indirect photolysis | Cyanobacteria | 0.36 | H2 and O2 |

Factors Affecting Biohydrogen Production

There are several factors that may directly or indirectly affect the biohydrogen production:

- Temperature: Thermophilic bacteria gives the maximum yield of hydrogen than the mesophilic bacteria. In simple words, the temperature is a factor, which depends upon the type of microorganisms and substrate used for hydrogen production.

- pH: Hydrogen-producing microorganisms work well below the pH of 5.5-6.0.

- Hydraulic retention time: For satisfactory hydrogen yields, the hydraulic retention time should be between 8-14 hours. Hydraulic retention time is also influenced by several factors, like the substrate’s composition, type of substrate, type of microorganisms etc.

- The partial pressure of hydrogen: The partial pressure of the hydrogen should be less in order to increase the yield of hydrogen production by 68%.

Future Prospects of Biohydrogen

Biohydrogen is considered to be a future fuel because of its high energy density, zero-emission of carbon dioxide and other factors, which we have discussed in this post. In addition to this, several studies are also going on to improve the technology and the production of biohydrogen.

There is a scope of development in each area, and our technology is improving day by day. Therefore, the use of oxygen-tolerant hydrogenase, increased production of hydrogen with a minimal substrate, development of a cost-effective method for the commercial production of hydrogen etc. are the areas of improvement.

Can thermotogoa used for future prospects of biohydrogen production?

Yes, Thermatoga maritima and Thermatoga neapolitana are the common species of bacteria used to produce biohydrogen, because of their high potential to yield hydrogen by fermenting sugars.

Thank you for this article.