Cheese production or Caseiculture makes the use of raw materials, bacterial culture, and rennet to process the end-product, i.e. cheese. Cheese comes in different varieties by the differences in the ingredients and the processing of cheese. Cheesemaking is accomplished by using milk, either in a raw or pasteurized form.

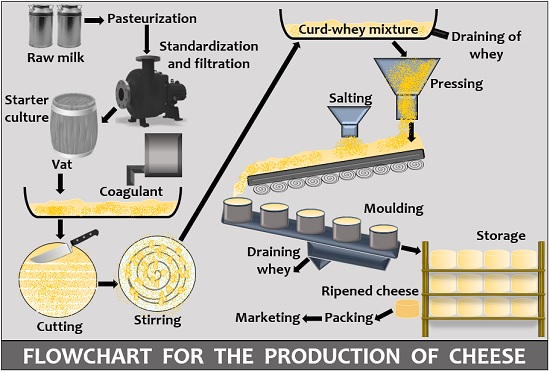

Depending upon the processing method, cheese is typically classified into rennet and processed cheese. The cheese-making process involves sequential steps like acidification, coagulation, separation of curd and whey, salting, moulding, ageing and packaging.

Cheese is a milk concentrate (contains casein and fat). In this post, we will discuss the definition and all the steps in the production process of cheese.

Content: Cheese Production

Definition of Cheesemaking

Cheesemaking refers to the production of cheese by using bacterial culture, enzymes and stabilizers to condense the milk proteins and fat and to preserve the cheese. The formation of cheese requires milk as a raw material. The production of acid after the fermentation by the starter culture and the salting step mainly add longevity to cheese.

Cheese is the milk product that forms by the coagulation of milk protein (Casein). The production of cheese is a lengthy procedure to carry out, which involves high maintenance and cleanliness of the equipment, and requires a long time.

Production Process of Cheese

The production of cheese includes the following sequential steps:

Sterilization

Like every industrial production, the process of cheese making also requires a sterile environment to avoid any microbial contamination.

Standardization of milk

Milk serves as a raw material source for cheese production, which can be obtained through milk-producing animals like a cow, buffalo, goat etc. The milk should be free of any off flavours, microbial contamination, antibiotics and chemical contaminants.

Subject milk to the centrifugation to clarify the small exogenous particles or somatic cells during the standardization process. This step generally optimizes the protein and fat ratio of the milk to produce superior quality cheese.

Pasteurization of milk

It reduces the spoilage of organisms and improves the environment for the growth of starter cultures. Cheese produced from raw milk requires ageing for a maximum of 60 days. After pasteurization or heating, cool the milk to the temperature necessary for the growth of the starter culture.

Inoculation of starter culture

Then, add the starter culture into the milk and subject it to heat (90 degrees Fahrenheit) for 30 minutes to ripen. Different cheese requires different starter culture to produce cheddar cheese. One can use the strains of Streptococcus bacteria (S. lactis or S. cremoris).

Nowadays, concentrated frozen starter cultures are also available in the market, which can be directly added to the milk. The ripening step promotes bacterial growth to start the fermentation process. Milk must be free from any antibiotics for the bacteria to carry out the fermentation.

Antibiotics may cause retardation in the growth of the starter culture and the production of acid, which in turn produce inferior quality cheese. Thus, the proper growth of starter culture lowers the pH of the media (by forming acid) and adds more flavour to the cheese.

Addition of rennet

Rennet aids in milk curdling or coagulation, as it functions as a coagulant. It coagulates the colloid casein to insoluble paracasein and carbohydrate-rich peptide fraction.

Also, left the milk undisturbed for about 30 minutes to obtain a firm coagulum. The alternative sources for the rennet enzyme are the blends of rennin and pepsin, fungi-based coagulants etc.

Fungi-based coagulants are widely used in the United States, including fungal strains like Mucor pusillus, Endothia parasitica etc.

Cutting of curd

This step allows the coagulum to ferment till it reaches a pH (6.4). Then, fraction the coagulum (curd) into small cubes with a cheese cutter.

This step allows easy separation of whey out of the curd. The coagulum fractioned into small cubes will produce low moisture cheese, while the large cubes will produce high moisture cheese.

Cooking the coagulum

Then, the fractions of coagulum are heated upto 38 degrees Celsius for the desired time. The time and temperature of cooking cheese usually differ in different processes of cheesemaking.

The cooking involves stirring the whey-curd mixture to obtain a compact mass of coagulum. This step is necessary for the following:

- For the control of acid production by the starter culture.

- To suppress the growth of spoilage microorganisms.

- To influence the curd texture.

- It also controls the amount of moisture content.

Draining whey

After cooking the whey-curd mixture, drain out the whey from the vat. The curd is obtained after the removal of whey, which appears as a knitted mat. The knitting of curd is a step that contributes to the texture by modifying the curd particles and produce a compact mass of cheese.

Brining

It is a process where salt acts as a stabilizer, which increases the shelf life of the cheese. You could either sprinkle salt over the loose curd or dip the freshly made cheese in the brine solution. Brining is a step necessary for cheese making:

- It suppresses the growth of spoilage microorganisms

- It also reduces the amount of moisture in the finished cheese.

- Salting also adds characteristic flavour and texture to the cheese.

Pressing of curd

After brining, keep the curd fractions in the cheese hoops. Then, apply hydraulic pressure to the coagulum. This step can be skipped in the case of cheese with an open texture.

In cheddar cheese, piling is done before pressing, where the fractions of curd are stacked one over the other and flipped periodically through cheddaring. This step expels more whey, thereby providing more compactness and characteristic shape to the cheese.

Ripening

Store the cheese in a cool and dry place, under controlled temperature and humidity upto the desired age. The ageing of cheese differs for several months to years, as recommended for cheese making.

This step allows enzymatically induced changes in the protein and fat fractions of cheese, which contributes to give a typical flavour, aroma, texture, etc.

Packaging

Finally, cut the cheese and package them into blocks by appropriately labelling the brand’s name along with the nutritional facts, market price, manufacturing date, expiry date and other product’s details.

It was interesting when you said that cheese production involves storing the cheese in a dry place while controlling the humidity and temperature. With this in mind, I would assume that the fabrication process of cheese must involve a humidification machine that won’t cause water accumulation. I could imagine how the right equipment can ensure the safe fabrication process of cheese.