Batch fermentation involves the fermentation of the substrate into products by microbial cells. This process occurs within a closed system. Unlike continuous culture, it requires the supply of limited nutrients into the fermentor.

Fermentation utilizes a living microbial cell suspension. It produces various valuable products through fermentation of the raw material or substrate.

In fermentation, a little inoculum converts carbohydrates into acids and alcohols. This process takes place under anoxic conditions. Within the fermentor or culture vessel, the fermentation of the desired substrate occurs.

Fermentation involves open and closed cultivation methods. Fermentation involves open and closed cultivation methods.

- Continuous culture is an open-culture system.

- Batch fermentation is a closed-culture system

- Fed-batch fermentation is a semi-open system.

This post discusses the definition, principle, diagram and procedure of batch culture fermentation. Also, you will get to know the advantages, disadvantages and applications.

Content: Batch Fermentation

- Definition

- Principle

- Batch Fermentation Process

- Growth Curve in Batch Culture

- Advantages

- Disadvantages

- Applications

- Conclusion

Batch Fermentation Definition

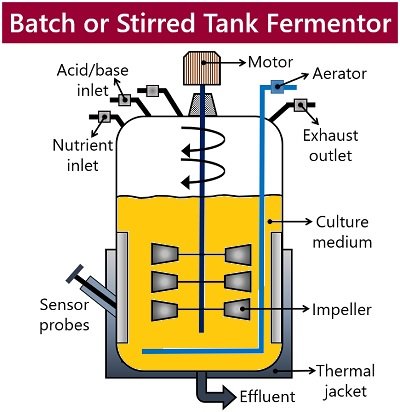

It refers to a technique in which microbial cells grow and multiply to convert substrates into products. Batch fermentation is performed using the stirred tank fermentor.

Batch fermentation itself clears that it involves batch-wise fermentation of the specific media. Microbial cells harness the added nutrients. Thereafter, they ferment raw materials into desired products within a predetermined fermentation time.

The factors affecting the fermentation time and rate include:

- Type of substrate you are adding

- Environmental conditions

- Inoculum concentration

- The product of interest

Batch culture depends upon the closed system fermentation. The culture volume remains the same.

Note: There is no addition or elimination of any content during the process.

After every batch, one can harvest the fermented broth culture for product recovery.

Principle

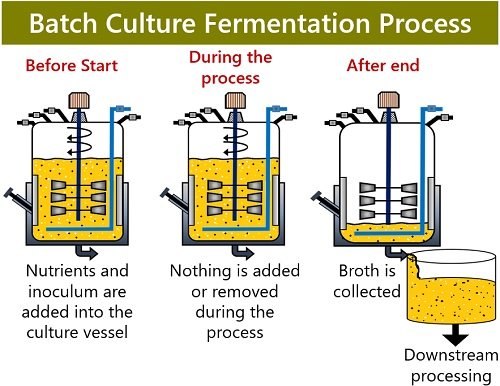

Batch culture follows a closed system fermentation. You should add all the required materials before the fermentation starts. The incubation of culture media proceeds for a specific fermentation period.

During this period, you can neither add fresh media nor discard spent media. Batch culture fermentation involves the commercial production of various products. This process takes place in separate batches.

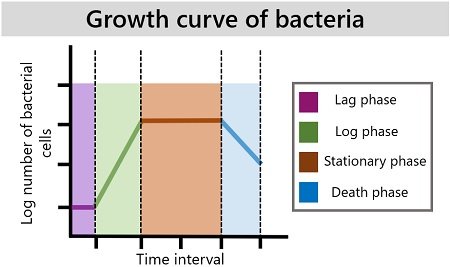

Here, other factors become limiting, as we supply limited nutrients for microbial growth. As a result, the bacteria show a sigmoid growth curve with four distinct phases.

Batch Fermentation Process

We can summarize the process into three consecutive stages:

Before starting

- Add sterile nutrient broth and other additives into the bioreactor through the nutrient inlet.

- Then, add inoculum (containing living microbial cells) into the bioreactor. This stage is called “Seeding”.

- Incubate the culture medium for a definite fermentation period under optimal physiological conditions.

During the Batch Fermentation

Aerator provides a continuous supply of oxygen in the form of air. To control the pH inside the culture vessel, you can add acidic or alkaline solutions.

The agitator allows uniform mixing of the culture broth. Also, it maintains a constant temperature. The foam sensor senses the froth formed in the bioreactor. And, to break the froth, we can add antifoaming agents.

Lag phase

During fermentation, microbial cells adapt to the conditions within the bioreactor. At this stage, they tend to grow in size and not in number.

Log phase

After two hours of the lag phase, cells enter the log phase. Here, they consume the nutrients to become metabolically active at a rapid pace. This leads to the production of primary metabolites.

There is an exponential increase in the number of bacterial cells. The concentration of nutrients, microbial cells and products in the reaction mixture vary with time.

But, you can not add the fresh media during the course of fermentation. Thereby the concentration of nutrition decreases gradually.

Stationary phase

As a result, microbial cells enter the stationary phase. At this stage, the production of secondary metabolites occur.

Decline phase

At last, cell growth declines due to the lack of nutrients and accumulation of toxic wastes.

After the end of Batch Fermentation

The obtained broth culture contains the desired product, cell debris and toxins. Finally, harvest the entire broth culture into the container.

Then, you need to settle the fermented broth culture for downstream processing. This involves four successive stages:

- Separation of microbial cell suspension through filtration, centrifugation and sedimentation methods.

- The concentration of remaining media through evaporation and precipitation methods.

- You can purify the desired product through the following techniques:

- Chromatography

- Adsorption

- Precipitation

- Crystallization methods.

- Drying of final product and waste disposal.

Growth Curve in Batch Culture

We can study the standard growth of bacteria in batch culture. Bacteria grow in a geometric fashion with typical four phases:

- Lag phase

- Log phase

- Stationary phase

- Decline phase

Also, you can determine bacterial generation time through a standard growth curve of bacteria.

Below, you can see the differences between the four growth phases of bacteria:

| Properties | Lag Phase | Log Phase | Stationary Phase | Death Phase |

|---|---|---|---|---|

| Meaning | It is the preparatory phase in which cells adjust according to the changing environmental conditions | It is an exponential phase in which cells grow and divide to double their population | The stagnant phase is where the cell population remains constant, and cells neither grow nor multiply | It is the decline phase where the number of viable cells decreases exponentially |

| Cell number | Cells increase in size, but not in number | Cells exponentially increase their population | The number of viable cells becomes equal to nonviable cells | The number of nonviable cells increases |

| Cell size | Small | Large | Small | Small |

| Occurrence | It occurs due to cells’ vigorous metabolic activity | It occurs when cells divide rapidly to double their population | It mainly occurs due to nutrient depletion | Cell density declines due to the accumulation of toxic wastes |

| Cellular activity | Low, cells adapt to new conditions | Very high | Very low | No cellular activity |

| Growth rate | Zero | Constant | Zero | Negative |

| Production | Cells prepare or adapt themselves to new environmental conditions | Cells are at active growth, and they produce primary metabolites like amino acids to make up the essential macromolecules | After active growth, cells form secondary metabolites like toxins, drugs etc. | Cells lyse and release the cellular content or cell debris |

Advantages

- Its setup is easy to make and run.

- It has wide applicability in laboratories and industries.

- Due to a closed fermentation system, there is less chance of contamination.

- It is easier in comparison to the continuous culture. Here, you can reinstall the setup, if contamination occurs.

- Complete conversion of a substrate into a product is possible.

Disadvantages

- Product isolation is difficult. This is because, fermentation broth contains nutrients, products, reagents, cell debris and toxins.

- It involves high downtime between two consecutive batches.

- It requires high labour cost and involves batch to batch variability.

Applications

- The technique helps microbiologists to observe the metabolic activity of the bacteria. Also, it helps in studying the cell physiology of microbes.

- It is efficient for the production of secondary metabolites such as antibiotics.

Conclusion

Thus, the batch fermentation method involves the batch growth of cell populations. Substrate, inoculum, and other additives are added at the initial stage of fermentation.

After that, the culture media is left undisturbed for a predetermined time. By the time of fermentation, microbial biomass converts the substrate into desired products. Product recovery is carried out at the end via downstream processing.

I agree with the advantages of batch fermentation. They reduce the risk of contamination in the process. For example, it’s more cost-effective than continuous fermentation.

Batch fermenting is a process where brewers can control the flavor and cost of their beer by using only the volume of wort desired at a time. This way, they can avoid continuous fermentation, which requires more infrastructure and equipment. I appreciate you uploading this blog.